Identify your selection: Name needs to be fewer than characters Choose a group: Unable to load your selection due to an error

In this lifecycle administration condition, a continued verification plan backlinks the operational elements of the standard technique, for example yearly solution evaluate and change Manage, to ongoing improvement initiatives for the production process. Fundamental to reaching these targets is the choice and trending of process parameters and high-quality attributes about their requirements. Control and operate charts making use of historic knowledge are useful for depicting any atypical and unpredicted shifts and patterns from the process parameters and top quality characteristics with time.

During the instance that Formerly sturdy batches shed consistency or products stability slips, the initial details can be utilized for troubleshooting.

For a number of batches created in the calendar year, a run chart could be manufactured by plotting highest and minimum amount values of the chamber strain for every batch. Different selections for plotting a run chart are offered during the portion underneath.

The above diagram of Lubrizol CDMO Evidently demonstrates the process of lyophilization from the pharmaceutical industry. The vials containing the drug are cooled and dried by using a condenser. A vacuum is additionally designed inside the application to hurry up the sublimation process.

12. Most important Drying (Sublimation) Heat is launched from shelf for the products under graded Handle by electrical resistance coils or circulating silicone.

Particularly, very best techniques for batch sizing resolve were talked over, including the influence of batch size on drying time, mindful collection of process parameters to stay away from item failure and to support lyophilization of the most batch dimensions to be a worst-scenario scenario. Also, batch dimensions overage to compensate for losses during manufacturing ended up regarded as.

Functionality cookies are used to be aware of and evaluate The real key efficiency indexes of the website which helps in delivering an improved consumer encounter for your site visitors. Analytics Analytics

In combination with the CQAs connected with the physicochemical and biological properties of the drug product, CQAs specific into the lyophilized products which include cake visual appearance, residual dampness, and reconstitution time can be Portion of the discharge Management technique. The PPQ protocol must include the rationale for that inclusion of every CQA and sampling frequency. For instance, deviation in process parameters, which include shelf temperature, chamber strain, and primary drying time, outside of the appropriate ranges for the duration of a lyophilization cycle can influence cake appearance, residual humidity, and reconstitution time, and for this reason these attributes are assessed through process validation. To display uniformity in drug solution excellent characteristics all through the batch of vials, intensive sampling is executed for PPQ batches. Residual moisture is one particular attribute that is definitely tested far more thoroughly than the rest of the CQAs. To exhibit drying uniformity through the lyophilizer(s), samples are collected from a variety of destinations around the cabinets. The selection of shelf places and the amount of samples gathered from Every single location really should be based on prior familiarity with variability in shelf area temperature and humidity. The destinations selected for sample collections needs to be the worst situations concerning impact on moisture content material. Shelf surface area temperature more info variability relative to cold and hot shelf temperature setpoints needs to be measured for the duration of First products qualification and periodic servicing.

Throughout this phase, the fashioned drinking water vapors are gathered by a condenser, which brings about the vapors to take on a solid variety.

In-situ freeze-drying - forming amorphous solids directly within just capsules: An investigation of dissolution enhancement for your badly soluble drug

Mechanical equivalency could be based on machines validations elements for example least/optimum shelf temperature, greatest sublimation level, minimum controllable stress, and condenser temperature even though process equivalency is set by building batches of exactly the same merchandise in Each individual lyophilizer and performing statistical Evaluation from the solution attributes in each lyophilizers (assay, water articles, and so forth.) to discover if product or service produced in equally lyophilizers is equivalent.

Qualification in the lyophilizer entails a number of useful tests built get more info to confirm which the utility units and the products run pursuing the process prerequisites about many of the predicted operating ranges. This tests is typically done in the installation and operational qualification (IQ/OQ) on installation and commissioning. Some of the qualification screening relevant to lyophilization process modeling and scale-up (such as, measuring the vial heat transfer coefficient and pinpointing the gear functionality curve) is not really normally carried out through IQ/OQ.

Crystallinity was determined by microscopic evaluation underneath polarized light and this process of manufacturing a crystalline freeze dried good could demonstrate handy within the manufacture of steady, Price tag-successful freeze dried pharmaceuticals.

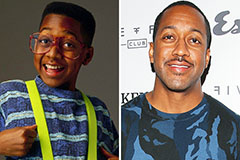

Jaleel White Then & Now!

Jaleel White Then & Now! Jenna Von Oy Then & Now!

Jenna Von Oy Then & Now! Loni Anderson Then & Now!

Loni Anderson Then & Now! Batista Then & Now!

Batista Then & Now! Jane Carrey Then & Now!

Jane Carrey Then & Now!